Desperate times call for desperate measures, and no time in history was as desperate as the time when the world’s most powerful nations were determined in destroying each other. It was time of the Second World War, and the allies were running out of essential resources needed to construct military and naval equipment. One of them was steel.

In the North Atlantic, the British fleets were taking a pounding against the German U-boats. Allied supply ships on their way across the ocean were being intercepted and sunk by German U-boats at an alarming rate. Planes could protect the ships, but they cannot be deployed in the middle of the ocean without aircraft carriers, and those things are massive and required enormous quantities of steel to manufacture, which was in short supply. What was needed was a way for aircraft to land and refuel without overtaxing already strained resources.

An artist's conception of Project Habakkuk.

A British scientist named Geoffrey Pyke, who worked at the Combined Operations Headquarters as adviser to the Chief, Lord Mountbatten, came up with a fantastic idea: make an aircraft carrier out of ice. Ice is hard, they don’t sink, and any damage could be easily repaired on spot by just freezing new chunks of ice into place.

Pyke, who had a penchant for outrageous ideas, suggested that a large piece of arctic iceberg be cut off and towed into the ocean. With its surface leveled, the ice would serve as a landing platform, and if they could hollow out the center, it would provide an ideal place to shelter aircraft.

Somehow, Pyke managed to sell the idea to Lord Mountbatten, who was able to convince Winston Churchill that the war could be won with ice. Churchill gave the go-ahead and the project was codenamed “Project Habakkuk”, a reference to a verse from the biblical book of Habakkuk: "... be utterly amazed, for I am going to do something in your days that you would not believe, even if you were told." (Habakkuk 1:5, NIV)

The aircraft carrier that Pyke envisioned was to be 2,000 feet long, 300 feet wide, and weigh more than 2 million tons. It’s torpedo-proof hull would be 40 feet thick. It was to be equipped with 40 dual-barreled turrets and numerous light anti-aircraft guns. The airstrip could accommodate up to 150 twin-engine bombers or fighters planes. There was one major problem: ice melts, but Geoffrey Pyke had a solution for that too. A massive cooling system consisting of a complex network of pipes would pump chilled refrigerant throughout the ship to keep the ice from melting.

Soon a 60-foot long, 1,000-ton prototype was built on Patricia Lake in the Canadian Rockies. A one horsepower refrigeration system kept the ship sufficiently cool to last all through the summer months.

During tests, some new problems arose. Although ice is hard, it is brittle. Besides, ice deforms under pressure, and a ship as large as Habakkuk would sag under its own weight. By a happy chance, two researchers at the Polytechnic Institute of Brooklyn, New York, made a breakthrough. They discovered that if wood pump or sawdust was mixed with water and frozen, the resulting material was fourteen times stronger than regular ice, and tougher than concrete. Experiments showed that this new material was highly resistant to compression, chipping, and even bullets. It could be machined like wood and cast into shapes like metal, and when immersed in water, it formed an insulating shell of wet wood pulp on its surface that protected its interior from further melting. This wonder material was named pykrete, in honor of Pyke.

The story goes that Churchill was bathing one day at his home in late 1942, when an excited Lord Mountbatten barged into his bathroom and dropped a chunk of pykrete into the tub. For the next several minutes, the two watched in amazement as the ice refused to melt in the warm water.

Another anecdote involving Lord Mountbatten’s enthusiastic demonstration that has been reiterated by a number of witnesses occurred during the Quebec Conference in 1943. To the conference, Lord Mountbatten brought two blocks, one made of ice and the other of pykrete, and placed them both on the ground. Then without warning, he pulled out his pistol and shot at the block of ice, shattering it to pieces. He then turned his gun to the pykrete and fired. This time the bullet ricocheted off the block and buzzed round the legs of the observers like an angry bee. The bullet grazed the trouser leg of Admiral Ernest King, and ended up in the wall.

The miraculous material was exactly what Geoffrey Pyke needed for the success of Project Habakkuk. Designs and plans for construction of the aircraft carrier were rushed ahead. Each Habakkuk ship, it was determined, would require 300,000 tons of wood pulp, 25,000 tons of fibreboard insulation, 35,000 tons of timber and 10,000 tons of steel. The original cost was pegged at £700,000.

But as design progressed, it became obvious that more steel reinforcement would be required as well as more effective insulation, and the cost estimate soared to £2.5 million (more than £100 million in today’s money). Steering also raised some problems. A ship so massive would have limited maneuverability and top speed of just 6 knots, that the Navy decided was too slow.

But the biggest problem was raw material itself. Like steel, wood itself was in short supply, and building even one Habakkuk would have seriously affected paper production. Add to that the complexity of building, insulating, and refrigerating such a large structure would have required time and manpower that none of the Allies could afford.

Eventually, Project Habakkuk was scrapped and more practical steps were taken such as setting up airfields in the Azores, which facilitated the hunting of U-boats in the Atlantic, adding larger fuel tanks to British aircraft to extend patrol time over the Atlantic, and increasing the number of escort carriers.

Today, the only tangible remains of Project Habakkuk lies at the bottom of Patricia Lake in Alberta, Canada, where the prototype was tested. A diving expedition to the site in 1985 found the wooden walls of the hull, an incredible jumble of cold air ductwork along with a great quantity of the bitumen used as part of the insulation, and an underwater plaque commemorating the project.

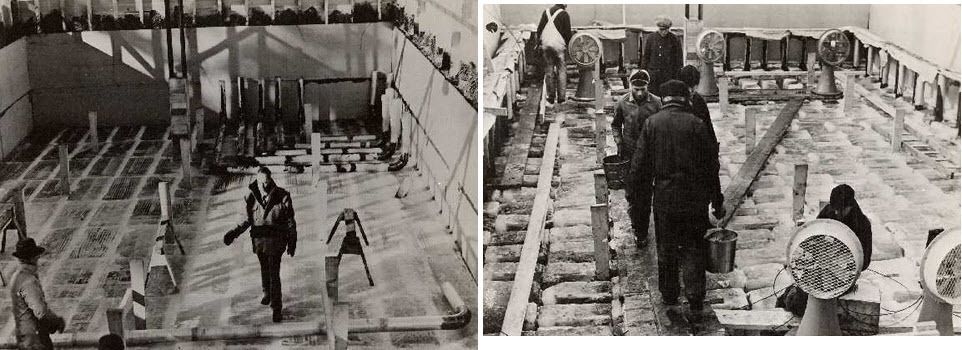

Building the prototype on Patricia Lake, Canada.

The wreck of the iceberg-ship under Patricia Lake. Photo credit: divermag.com

Sources: Wikipedia / Interesting Thing of the Day / www.goodeveca.net / Gizmodo / Untested Arms

UNBELIEVABLE !!!!

ReplyDelete